One fine morning in August 1888, a German woman named Bertha Benz did something outrageously bold. She snuck out at dawn, loaded her two teenage sons into a peculiar three-wheeled contraption built by her husband Karl, and set off on the world's first road trip – without permission¹. This primitive car had a single-cylinder engine making less than one horsepower (about 0.88 hp) and a top speed around 10 mph on a good day. There were no gas stations, so Bertha stopped at pharmacies along the way to buy fuel (a cleaning solvent called ligroin, effectively making those pharmacies the first gas stations). Water for cooling had to be refilled every few miles, and when the wooden brakes wore out, she persuaded a shoemaker to nail on new leather linings. At one point she even plugged a leaky fuel line with her hat pin and insulated a frayed wire with her garter – MacGyver would be proud. After 66 miles of rattling along rutted wagon paths, Bertha reached her destination, proving to a skeptical world that the "horseless carriage" could actually be useful. Karl Benz got the publicity he needed, and the age of the automobile was born.

That delightful tale – complete with the first engine breakdowns and bush-league repairs – hints at just how mysterious and miraculousearly cars seemed. A contraption that "fumph-fumph-sneeze"s to life in a cloud of oil vapor and smoke, carries you away under its own power, and maybe even breaks the law (Bertha's jaunt was technically illegal) – what sorcery was this? Of course, it wasn't sorcery at all. It was engineering – specifically, the internal combustion engine, a technology that would soon dominate the world's roadways. In this Substack-style journey, we'll demystify how a combustion engine actually works, from the basic "suck, squeeze, bang, blow" cycle to the intricate dance of pistons, cams, and crankshafts inside. We'll see why gasoline engines overtook steam and electric rivals, learn what all those engine parts and automotive buzzwords really mean, and sprinkle in some colorful car lore along the way (feuding Ferrari and Lamborghini? a car that ran on tequila and perfume? we've got that). By the end, you'll have a new appreciation for the controlled explosions under your hood – and you might finally understand what your mechanic is babbling about. So let's turn back the clock and start at the beginning: why did the gasoline engine win, and how on earth does it actually work?

The Road to Dominance: A Brief History of Gasoline Power

In the late 19th century, the race to motorize transportation was wide open. Gasoline (petrol) engines were one approach – but steam engines and electric motors were serious contenders, and in some ways early superior. Steam cars were quiet and powerful, with a simple elegance that many early motorists preferred. Electric cars were dead simple to operate (no cranking, no gears) and emitted no smell or noise. In fact, around 1900, a significant number of cars on American streets were electric. So why did the internal combustion gasoline engine ultimately conquer all? The answer comes down to a mix of technology, energy, and practicality.

First, gasoline packs a staggering amount of energy in a small package. Even by modern standards, nothing readily available beats liquid hydrocarbon fuel. Around 1900, the best batteries could only store about 10 watt-hours per pound, whereas gasoline contains roughly 6,000 watt-hours per pound². In plain English, that means you'd need a battery weighing hundreds of pounds to carry the energy that just one pound of gas holds. Gasoline's energy density (and the ability to refill a tank in minutes) gave combustion cars a huge advantage in range and speed. Electric cars of the early 1900s were fine for short city trips – 20-50 miles at pokey speeds – but long-distance or high-speed driving was out of reach. As one frustrated journalist wrote in 1908 about Thomas Edison's failed attempts to improve batteries, "Mr. Edison's bunk has come to be somewhat of a joke – a real joke." The energy storage problem simply wasn't solved yet.

Steam cars, meanwhile, had their own Achilles' heel: while a steam engine can be very powerful, it needs a boiler to produce steam, and small boilers in cars were finicky. Early steam autos (like the Stanley Steamers) required intense attention from the driver – you had to manage steam pressure, water level, and fuel for the burner constantly. Getting a steam car ready in the morning meant a 20-minute ritual of valve-twiddling and waiting for pressure to build. One enthusiast quipped in 1900 that with a steam car, "the motorist who cannot afford to stop for a few moments after a hundred-mile run, and smoke a cigarette while an ostler throws in a few buckets of water, had better take the railway train." Most folks, it turned out, did mind stopping every 60-100 miles for water and an extended smoke break. The gasoline car was hardly user-friendly at first (early drivers needed to manage chokes, spark timing, crank starters, etc.), but it rapidly improved. By 1912, Cadillac introduced Charles Kettering's electric self-starter³, eliminating the dangerous hand crank and letting drivers start a gas engine with a push of a button. Transmissions got better, reliability improved, and driving a gas car became easier year by year.

Another decisive factor was mass production and cost. Henry Ford's Model T, introduced in 1908, wasn't the first car or the best car – but it was the first affordable car for ordinary people. Ford obsessively focused on manufacturing efficiency, famously saying customers could have the Model T in any color "so long as it is black"⁴. (Black paint dried fastest and was cheapest, so standardizing on black helped speed up the assembly line.) By cranking out millions of identical cars, Ford drove the price of a Model T down to ~$600 by the mid-1910s – at a time when an electric car cost around $2,800⁵. In other words, you could buy four Model T Fords for the price of one electric runabout. The results were predictable: gasoline cars flooded the roads. In 1908, only about 200,000 motorcars existed; by 1917, there were 3.5 million and climbing fast. Steam and electric car companies went belly-up one by one.

It wasn't just technical limitations that sidelined the alternatives; there were also quirks of culture and infrastructure. Electric cars became associated with women drivers (who appreciated their cleanliness and ease) – and in the sexist climate of the time, that ironically hurt their image among men. Power companies never set up widespread charging networks (some early 20th-century visionaries imagined battery-swap stations, but it never took off), whereas oil companies aggressively built gas stations everywhere. And once the U.S. discovered vast petroleum reserves in Texas and elsewhere, gasoline became cheap and plentiful. By the 1920s, the contest was essentially over: the thundering internal combustion engine reigned supreme for the next 100 years.

To be clear, internal combustion's victory wasn't because it was environmentally friendly or quiet or smooth. It won because it offered performance, range, and convenience that others couldn't match at the time. A gas engine could make a car go faster and farther – and get cheaper every year. Consumers wanted freedom to travel, and the roaring engine under the hood delivered. (Even racing played a role – early motorists loved speed and power. As legendary engineer Enzo Ferrari later quipped, "Aerodynamics are for people who can't build engines"⁶, implying that to go faster, you simply build a more powerful motor.) By mid-century, automakers were squeezing out ever more horsepower: from the 40 hp Model T to the hundreds of horses in mid-century V8s. The internal combustion engine became the heart of the automobile, and car culture grew up around its visceral charms – the sound of a V-twin or a V8, the thrill of accelerating, the mystique of horsepower and torque.

Today, in the 2020s, we're finally seeing electric vehicles stage a serious comeback as battery technology catches up. But make no mistake: the gasoline engine had an astonishing run, and it's not dead yet. To really appreciate this invention – which transformed the world in the 20th century – we need to peek inside and see how it works. What exactly happens in that metal beast that Bertha Benz coaxed into motion over 130 years ago? Let's lift the hood and find out.

How an Internal Combustion Engine Actually Works

At its core, a gasoline internal combustion engine is a heat engine. It burns fuel inside the engine (hence internal combustion) to release energy, which pushes pistons that turn a crankshaft and ultimately spin your car's wheels. This is in contrast to an old-fashioned steam engine, which burns fuel outside in a boiler to make steam (external combustion). The genius of the internal combustion design is how compact and fast it is – it continuously fires explosions inside enclosed cylinders to keep things moving.

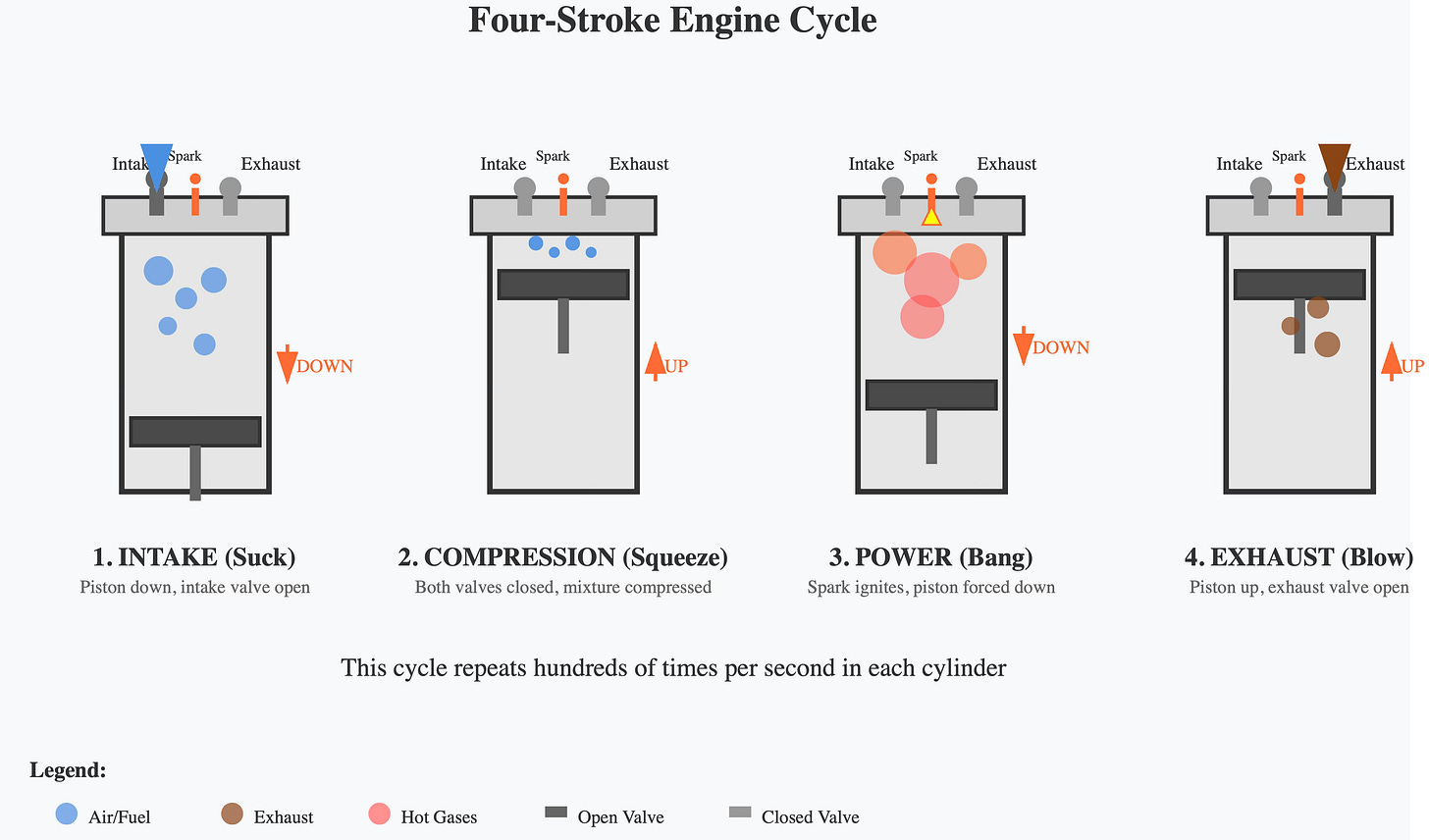

If you've ever heard a mechanic summarize a four-stroke engine as "suck, squeeze, bang, blow," that cheeky phrase is a pretty accurate snapshot of the process. A more polite term is the Otto cycle (named after Nikolaus Otto, who developed the four-stroke engine in 1876). Whatever you call it, here are the four strokes that happen over and over in each cylinder of a typical car engine⁷:

Intake (Suck): The piston moves down, sucking in a mixture of air and fuel. A valve opens to let the mixture flow in. It's like the engine taking a deep breath of combustible air-fuel vapor.

Compression (Squeeze): The piston then moves up, squeezing that air-fuel mixture into a much smaller space. Both valves are shut, so the chamber is sealed. The mixture gets highly pressurized and hot.

Power/Combustion (Bang): At the peak of compression, a spark plug emits a spark (in a gas engine) and Bang! – the fuel ignites. The mixture rapidly burns, creating hot expanding gases that force the piston to slam downward with great force. This is the power stroke – the one that actually delivers usable energy to the engine, turning the crankshaft.

Exhaust (Blow): Finally, the piston comes back up and blows out the spent combustion gases. An exhaust valve opens, and the burned gas is pushed out into the exhaust manifold and out the tailpipe.

In a typical car engine, this four-stroke cycle is happening in multiple cylinders one after the other, in a staggered sequence. For example, a four-cylinder engine will time the cycles so that when one cylinder is firing (power stroke), another is exhausting, another is intaking, and another is compressing – keeping the engine balanced and delivering a steady stream of power pulses. The up-and-down motion of the pistons is converted into rotation by the crankshaft (more on that soon). Each cylinder fires perhaps dozens of times per second. For instance, at 3,000 RPM (a moderate engine speed), each piston completes 50 cycles per second! Modern engines are precisely engineered and computer-controlled to choreograph these mini-explosions in perfect rhythm, over and over, for hours on end.

It's worth noting that not all internal combustion engines follow this exact four-stroke cycle. There are two-stroke engines (common in old lawn mowers or chainsaws) that combine steps to fire every revolution, and there are exotic designs like rotary (Wankel) engines which use a triangular rotor instead of pistons. But the vast majority of car engines today are four-stroke piston engines as described. Diesels are also four-stroke, but with one key difference: they don't have spark plugs. In a diesel engine, the air is compressed so much that it becomes extremely hot, and when diesel fuel is injected, it ignites from the heat of compression alone – no spark needed. Diesel fuel has properties that allow this (and that's also why diesels have that distinctive clattery sound at idle). Gasoline engines, by contrast, rely on a timed spark to ignite a more volatile air-fuel mix. Different approaches, but both run through the same four-stroke dance.

Another key point: internal combustion engines produce a lot of waste heat. Only roughly 20–30% of the fuel's energy actually turns into motion; the rest is dissipated as heat through the exhaust and cooling system. That's why engines need coolant (circulating water/antifreeze through a radiator) to keep from melting down, and why your car's heater can repurpose some of that heat to warm the cabin. It's ironic – the engine under your hood is essentially a powerful air pump with controlled fire inside, but it's not terribly efficient. Still, for over a century, engineers kept refining it, extracting more power and reducing emissions while maintaining reliability. We've gone from Bertha's one-cylinder wheezer to engines with 8, 10, 12 or even 16 cylinders, capable of propelling cars past 200 mph. Let's now look at who's who inside an engine – all those parts you've heard of (pistons, camshafts, spark plugs, etc.) – and see what roles they play in this fiery symphony.

Meet the Main Parts: Key Components of an Engine

Now let's break down the engine's cast of characters. Think of an engine as a finely tuned orchestra of metal parts – each has a specific job, and when all work together, you get that smooth (or sometimes lumpy) roar under the hood. Here are the key components you should know about, and how they relate to the "suck-squeeze-bang-blow" process:

Cylinder & Piston: The cylinder is the round chamber where the magic happens – basically a sturdy metal tube (machined into the engine block) that guides the piston's movement. The piston is a solid metal plug that moves up and down in the cylinder like the plunger in a syringe. During intake, the piston goes down to suck in air/fuel; during compression, it rams upward to squeeze the mix; the combustion bang forces it down again on the power stroke; and then it comes up to push out exhaust. Pistons are usually made of aluminum alloy and have rings around them to seal against the cylinder walls and control oil. If you peeked inside a working engine, you'd see pistons reciprocating furiously – in a four-cylinder, usually two going up while two go down, in a kind of balancing act. Fun fact: in a high-revving engine, pistons can be moving hundreds of times per second and experiencing enormous acceleration forces as they change direction at each stroke's end.

Connecting Rod & Crankshaft: The connecting rod (or con-rod) connects each piston to the crankshaft – it's the arm that links the up-down motion to the rotating shaft. The crankshaft is like the backbone of the engine, a hefty shaft with offset cranks (journals) for each cylinder, kind of like the pedals on a bicycle. As the piston moves down on a power stroke, it pushes the connecting rod which turns the crank slightly; with multiple cylinders, the crankshaft spins smoothly as each piston takes its turn pushing. In short, the crankshaft's job is to convert linear piston motion into rotational motion. That rotating crank is ultimately what delivers torque to your transmission and wheels. Crankshafts are made of forged steel or iron and spin on big bearings. They also have counterweights to keep things balanced. Attached to one end of the crankshaft is usually a flywheel – a heavy wheel that stores rotational energy to smooth out the power pulses (and on manual cars, the flywheel also has a friction surface for the clutch). On the other end of the crank, usually, is a pulley that drives belts for accessories and often the timing belt/chain for the camshaft. Think of the crankshaft as the engine's output shaft – everything else in the engine is kind of there to keep the crank turning with power.

Valves & Camshaft: If the piston and crank are the muscle, the valves and camshaft are the choreographed timing system that make sure the "doors" open and close at the right moments⁸. Each cylinder typically has at least two valves: an intake valve that opens to let the fuel/air mix in, and an exhaust valve that opens to let burned gases out. These valves are like spring-loaded mushrooms that seal against the engine's cylinder head. Enter the camshaft – often called the "brain" or "maestro" of the engine. The camshaft is a long shaft with egg-shaped lobes (cams) on it. As the camshaft rotates (in sync with the crankshaft via a timing belt or chain), each lobe pushes on a valve (either directly or through a rocker arm) to open it at a precise time, then a spring snaps the valve shut as the lobe rotates away. The camshaft thus controls when and how long each valve opens. During intake stroke, the intake valve must open; during exhaust stroke, the exhaust valve opens, etc., all timed perfectly. Most modern car engines have at least one camshaft per cylinder bank. Engines described as "SOHC" (single overhead cam) or "DOHC" (dual overhead cam) refer to how many camshafts are on the cylinder head. "Overhead cam" means the camshaft is up top in the head, directly operating the valves (often via small rocker arms or lifters). The older style is "overhead valve" or pushrod engines, where the camshaft is down in the engine block and uses long pushrods to actuate valves in the head – common in classic American V8s. Overhead cams allow higher RPM because they have fewer moving linkages (pushrods can bend at high speed), which is why most high-performance engines (and all Formula 1 engines) use overhead cams. The camshaft is linked to the crank by a belt or chain so that it turns exactly half the speed of the crank (because one full engine cycle takes two crank revolutions). If that timing gets off (say a timing belt snaps), valves can open at the wrong time and collide with pistons – a catastrophic failure. So, the cam and crank timing is critical.

Spark Plug & Ignition: Each cylinder has a spark plug (in a gasoline engine) typically screwed into the top of the combustion chamber. At just the right moment near the end of compression stroke, the spark plug emits a high-voltage electric spark that ignites the compressed fuel-air mix. That spark needs to be powerful (20,000+ volts) to jump the gap and start the flame kernel. A car's ignition system (coil or coil packs) generates these sparks timed by the engine's control system. Older engines used a distributor (a rotating electrical switch gear driven by the cam) to time the sparks to each cylinder; modern engines use computer-controlled ignition with one coil per plug or a small set of coils. Without a spark, a gasoline engine won't run (diesels, again, being different since they ignite by compression heat). Spark plugs need periodic replacement, and they're a common cause of misfires if fouled or worn. They truly are the "firestarter" of each mini-explosion.

Fuel System (Injector or Carburetor): An engine needs fuel mixed with air – roughly 1 part fuel to 14 parts air by mass for gasoline. How does fuel get into the cylinder? Early engines like Benz's used a primitive evaporation carburetor. For much of the 20th century, carburetors were common – devices that use engine vacuum to suck fuel into the incoming air stream, mixing it into a vapor. Carburetors have numerous tiny passages and jets and were notoriously finicky (you might remember needing to pump the gas and choke the engine to start old cars – that was feeding the carb). Today, fuel injection is universal. Fuel injectors are essentially computer-controlled spray nozzles that squirt fuel into the air intake (or directly into the cylinder in some engines) in precise amounts. Electronic fuel injection metered fuel far more accurately, improving power, economy, and starting. So when you press the accelerator, you're not directly dumping fuel; you're actually just telling the engine computer "give me more power," and it opens the throttle (letting in more air) and increases injector fuel accordingly. The result: a combustible mix ready for the spark. (Diesel injectors, by the way, spray diesel directly into the cylinder under very high pressure at the moment of combustion – a different scheme.) The upshot is: fuel + air + spark are the ingredients for each bang.

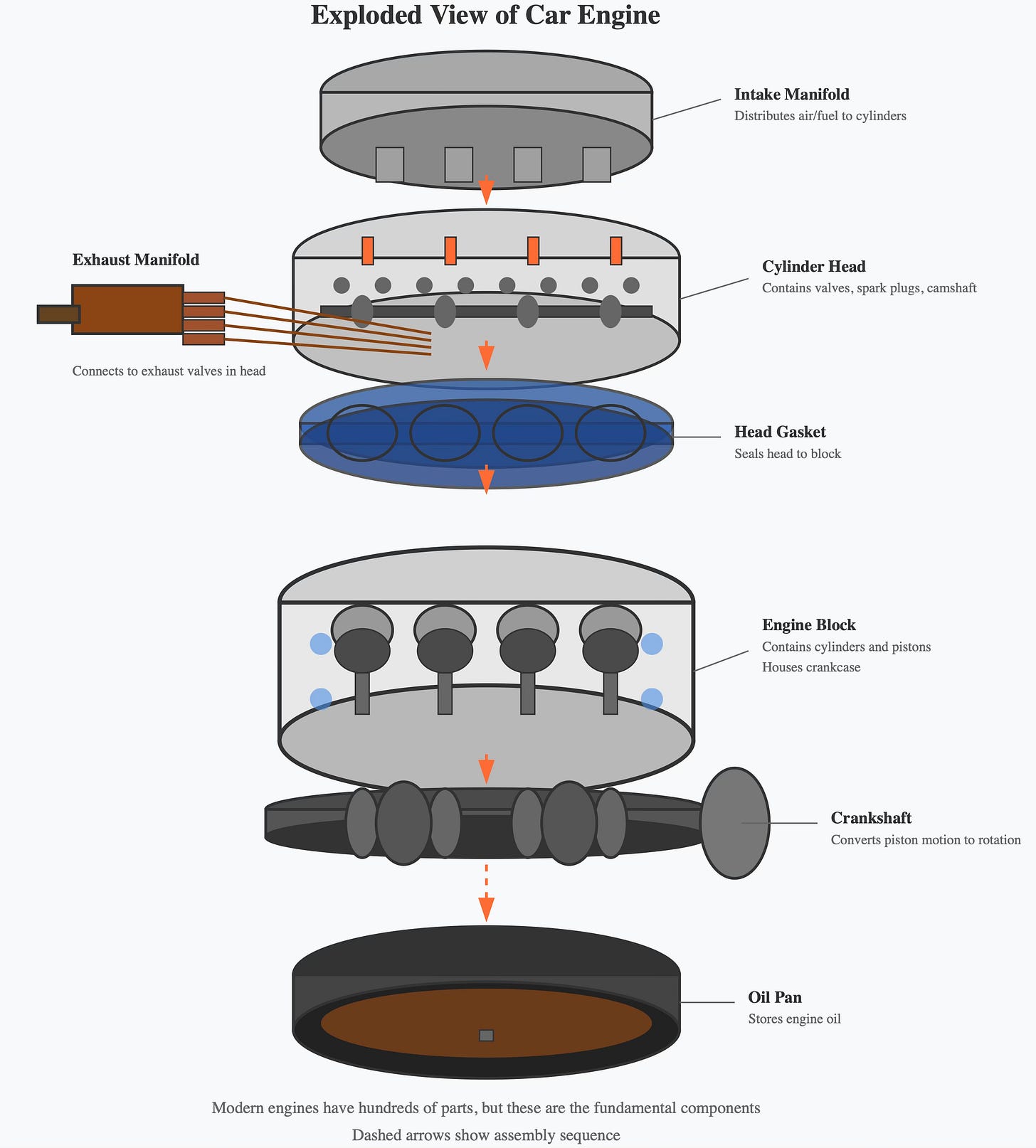

Engine Block & Head: These are the major structural parts. The engine block is the heavy metal chunk (usually cast iron or aluminum) that contains the cylinders and crankcase. It's the foundation – often riddled with passages for coolant and oil. The cylinder head sits on top of the block, sealing the cylinders with a head gasket in between. The head contains the valves, spark plugs, and often the cams. It's typically aluminum even if the block is iron. Coolant flows through both block and head to carry away heat. These parts endure extreme pressures and temperatures; for example, combustion pressures can exceed 700 psi, and peak flame temperatures can be ≈ 2500°C. No wonder they're made of robust stuff!

Other bits: There are many other components (we could spend a whole essay on them) but a few worth a quick mention: piston rings (seal the piston, control oil), oil pump & sump (lubricates all those moving parts with oil stored in the oil pan), cooling system(water pump, radiator, thermostat – preventing overheating), exhaust manifold (collects exhaust from each cylinder into the exhaust pipe), intake manifold (distributes air to each cylinder), and often turbochargers or superchargers (coming up next section) attached to the intake/exhaust for boosting power. There are also sensors everywhere in modern engines – oxygen sensors in exhaust, airflow sensors, throttle position, knock sensors, cam/crank position sensors – all feeding data to the engine control unit (ECU) computer which adjusts spark timing, fuel, etc. on the fly. But fundamentally, if you've got a block, pistons, crank, valves, cam, spark, and fuel system, you've got a functioning engine. Everything else is supporting infrastructure to make it smooth, durable, and clean-running.

Finally, not all car "engine" parts are under the hood! Often when you talk with a mechanic, they'll mention drivetrain and chassiscomponents in the same breath. Two common terms that confuse people are tie rod ends and suspension components – which are notpart of the engine at all, but worth understanding:

Tie Rod End: A tie rod is part of your car's steering system⁹. When you turn the steering wheel, through some linkages or a steering rack, ultimately a tie rod pushes or pulls on the steering knuckle (the part that holds the wheel hub) to swivel the front wheels left or right. The tie rod ends are the small flexible joints at the ends of the tie rod that connect to the wheel hub assembly. They allow a bit of up-down movement (for suspension) while transmitting the steering force. In short, tie rod ends tie your steering gear to the wheels, acting as pivot points. If a tie rod end wears out or is loose, you'll get sloppy steering, wandering alignment, or clunking noises, and it's a common item to be replaced in older cars. You literally cannot steer if the tie rod breaks, so it's an important link (imagine breaking the reins of a horse – not good).

Suspension (Shocks & Springs): The suspension system are all the parts that connect the wheels to the car's body and allow for a smooth ride and control¹⁰. This includes the springs (which could be coil springs or leaf springs) that support the car's weight and absorb bumps, and the shock absorbers (dampers) or struts that dampen the spring's motion so the car doesn't bounce endlessly. The purpose of suspension is to keep the tires in contact with the road as much as possible, while isolating the passengers from bumps. Without suspension, every little bump would jolt the car and you'd probably lose control on rough roads. So, springs take up the road shocks, and shock absorbers (filled with oil or gas) provide resistance to slow down the spring's oscillation. The suspension also includes things like control arms, bushings, sway bars – but those get beyond our scope. Just know that when your mechanic says you need new "shocks" or "struts," it's to restore the car's ride and handling. And if you have a "suspension problem," it's separate from the engine – it's about the wheels and body.

Now that we know the cast of players and how the basic engine cycle works, let's decode some of the jargon and buzzwords that often surround engines and performance. What do people mean by "torquey engine," why do gearheads brag about horsepower, and what on earth is the difference between a turbo and a supercharger? Let's translate these from gearhead-ese to plain English.

Decoding Gearhead Lingo: Torque, Horsepower, RPM & More

When car enthusiasts talk, it can sound like alphabet soup and gibberish: "300 horsepower at 6000 RPM, 280 pound-feet of torque at 4000, turbocharged DOHC inline-four, redlines at 7,000, with an LSD and ABS, OMG!" Let's focus on a few of the most common engine-related buzzwords you'll encounter and clarify what they really mean:

Horsepower vs. Torque: These two terms are the bread and butter of engine specs, and they're often misunderstood. In short, torque is a force – a twisting force – and horsepower is a measure of power – the rate of doing work. An engine produces torque (twisting force on the crankshaft) and if you apply that torque at a certain speed (RPM), it equates to horsepower. Mathematically, horsepower = torque × RPM ÷ 5252 (for torque in lb-ft)¹¹. What this means in practice: torque indicates how much grunt or pulling force the engine can provide, while horsepower indicates how quickly it can apply that force. An engine with high torque at low RPM will feel strong and effortless (think of an American V8 or a diesel – great for towing or launching off the line), whereas an engine that can rev very high to make big horsepower can ultimately go faster if geared right (think of a motorcycle or Ferrari engine – lower torque, but lots of horsepower by revving to 9000 rpm). A useful analogy: torque is like the strength to turn a wrench, horsepower is how fast you can turn it. As MotorTrend nicely puts it, "torque represents the work an engine can do, and horsepower is its ability to do that work quickly." If you want brisk acceleration, both matter – torque gives you that immediate shove, and horsepower (which takes into account speed of rotation) determines how quickly you can build and sustain speed. Ultimately, horsepower is the more comprehensive measure of engine performance (a car with more peak horsepower will usually be faster than one with less, all else equal), but torque gives the character – a "torquey" engine feels responsive and strong in the mid-range, a "peaky horsepower" engine might feel weaker at low rpm but then rush as it climbs toward redline. Both are inseparable in physics (they are linked by that formula), but now you know the distinction.

RPM & Redline: RPM stands for revolutions per minute, meaning how many times the engine's crankshaft (and each piston) completes a full rotation every minute. It's literally the speed of the engine. Idle might be ~800 RPM (barely ticking over), and a small car engine might redline around 6,500–7,000 RPM, while a sport bike engine might scream to 12,000+ RPM. The redline is the maximum safe engine speed – usually indicated by a red zone on the tachometer gauge on your dash¹³. Revving beyond the redline can cause valve float (valves failing to close in time and possibly hitting pistons) or other failures. Modern cars have rev limiters in the engine computer that cut fuel or spark at redline to prevent over-revving. Interesting fact: different engines have different redlines based on design – e.g., diesel engines typically have much lower redlines (~4500 RPM) because diesel fuel burns slower and the engines are built for high torque at low speed. Gasoline engines, especially performance ones, can rev high because they have lighter components, more aggressive valve timing, etc. – some motorcycle engines can rev to 15-19k RPM, Formula One race engines even hit 18,000+ RPM (though modern ones are limited to ~15k). Hitting the redline briefly isn't usually immediately damaging (and some spirited drivers enjoy taking each gear to redline), but living at redline will stress the engine and cause extra wear. In normal driving, you'll rarely approach redline unless accelerating hard. The redline is basically a do-not-exceed zone set by the engineers – stick to it, and your engine should have a long life; go past it regularly, and you may be visiting the mechanic for an expensive rebuild.

Turbocharger vs. Supercharger: These are two types of forced induction devices – meaning they force more air into the engine than it would ingest naturally, thereby allowing more fuel to burn and making more power¹². The idea is like "steroids" for your engine: cram more oxygen in, make a bigger bang, get more horsepower from the same displacement. The difference lies in how they're powered. A turbocharger (turbo) is driven by the engine's own exhaust gases – it's essentially a pair of fans on a common shaft: exhaust spins the turbine on one end, which drives a compressor on the other end that sucks in and compresses fresh air into the engine. A supercharger, by contrast, is driven mechanically by the engine – usually a belt off the crankshaft turns the supercharger's compressor directly. So a turbo is "free" energy (using waste exhaust heat) but has a delay (turbo lag) because it takes time for the exhaust to spin it up; a supercharger gives immediate boost (it spins with the engine) but draws some power from the engine to do it. Both achieve the same goal: pressurize the intake (for example, at 8 psi of boost, you're stuffing ~50% more air into the engine than atmospheric pressure alone). Turbos have become extremely common in modern cars because they can significantly improve efficiency (get more power out of a smaller engine when you need it, but then cruise without boost to save fuel). Superchargers are often seen in muscle cars or high-end sports cars for instant throttle response and power (e.g., a Hellcat V8 has a supercharger whine, whereas many European performance cars use turbos and you hear the whoosh and whistle). There are also differences in complexity – turbos run very hot (exhaust heat) and need good oiling, etc., while superchargers are bulky and put strain on the belt drive. But now you know: both are compressors, one is exhaust-driven (turbo), one is engine-driven (supercharger). End result: boost. (As a side note, these aren't new – the first supercharged production cars appeared in the 1920s, and turbos in production cars in the 1960s. Today's turbo tech, with computer-controlled boost, is just far superior.)

Overhead Cam, DOHC, SOHC, Pushrod: We touched on this in the parts section, but here's the quick decode. OHC means overhead cam – the camshaft is in the cylinder head over the valves. SOHC means a single cam per head operating both intake and exhaust valves (so e.g. a straight-4 SOHC has one cam total; a V6 SOHC has two cams, one on each bank). DOHC means dual cams per head – typically one cam for intake valves, one for exhaust valves on each bank. So an inline-4 DOHC has two cams total; a V8 DOHC has four cams (two per head). More cams allow more precise control (and often four valves per cylinder – e.g., two intake, two exhaust – which DOHC setups commonly use for better airflow). Pushrod or "OHV" (overhead valve) engines have the cam in the block, using pushrods to actuate rocker arms that open the valves in the head. This is an older style but still used in some engines (like the Chevrolet small-block V8 in the Corvette). Pushrod engines usually have only two valves per cylinder and lower rev limits (valve float tends to occur at lower rpm because the valvetrain is heavier). Overhead cam engines dominate modern designs, especially for multi-valve high-rev applications. Each design has pros/cons: pushrod engines are physically smaller (more compact V8) and can make lots of low-end torque; OHC engines can rev higher and breathe better at high rpm. When someone says "32-valve V8", that implies DOHC (since 4 valves per cyl × 8 cyl = 32, and you likely have dual cams). If someone says "big cam" in an engine, they mean a cam with a more aggressive profile for longer valve open times – a common hot-rodding upgrade for muscle cars. And if your mechanic says your "camshaft is worn" or "timing chain for the cam is loose", that's critical to fix – remember, cam timing is everything for keeping the engine in sync.

"Hemi" Engine: A bit of a buzzword courtesy of Chrysler's marketing – "Hemi" refers to an engine with hemispherical combustion chambers (the top of the combustion chamber is dome-shaped like half a sphere). This was an innovation in the mid-20th century that allowed larger valves and a straighter path for airflow, improving power. Chrysler's 1950s-70s Hemi V8s became legendary in muscle cars. Modern Chrysler/Dodge still market "HEMI" V8 engines, although their design has evolved. The term isn't as technically important as it once was (many engines have semi-hemispherical chambers now), but if someone brags about a Hemi, they're usually implying old-school brute power. Just smile and nod – the Hemi engines are strong, but a lot of it is mystique and branding (sorry, Dodge guys).

Displacement (Liters, CC, Cubic Inches): This is the total volume of all cylinders in an engine. For example, a "2.0-liter four-cylinder" means each cylinder might be 0.5 liters and with four of them you have a 2.0 L engine. American cars used to be described in cubic inches (the classic Chevy 350 is 350 cu in, which is about 5.7 liters). Generally, more displacement = more potential power/torque, because you burn more fuel-air mix per engine cycle. It's like having a bigger engine "lung." However, enhancements like turbos can make a small displacement behave like a bigger one by cramming in more air. There's an old saying, "there's no replacement for displacement," meaning bigger engines make more easy power – but tell that to the engineers extracting 400 hp from a 2.0L turbo four (it can be done, at high boost!). In any case, displacement is just an engine's size. It's one reason a 1.5L economy car engine doesn't perform like a 6.2L Corvette V8 – the latter moves a lot more air/fuel each revolution.

V8, V6, Inline-4, etc.: This simply describes the cylinder configuration. V8 means 8 cylinders in a "V" layout (two banks of 4 at an angle), common in trucks and American performance cars. V6 is 6 cylinders in a V (often 60° or 90° angle V). Inline-4 (I4) means 4 cylinders in a straight line – the most common car engine format worldwide. Inline-6 is 6 in a row (BMW is famous for smooth inline-6 engines). Flat-4 or Flat-6 means cylinders opposed 180° – also called boxer engines (Subaru and Porsche use these; they lay flat, pistons opposite each other). The configuration affects smoothness and packaging. V12 engines (12 cylinders, often in high-end luxury or sports cars like Ferrari/Lamborghini) are renowned for smoothness (because having 12 smaller pulses overlapping makes power delivery very seamless) and a unique exhaust note. The more cylinders (for a given displacement), the more but smaller bangs you have, which can make an engine smoother and able to rev higher (but also heavier and more complex). That's why a 12-cylinder can rev to 8000 rpm silkily, whereas a big single-cylinder (like a lawnmower) shakes and can't rev high. Knowing this, you can also guess an engine's character: a 2.0L four-cylinder might be a bit buzzy at high rpm and have power in mid-high range; a 5.0L V8 will likely have gobs of torque down low and a burly sound; a V12 might not have huge torque but will rev and sound like a symphony. No configuration is outright "better" – they each have trade-offs. Manufacturers choose based on the vehicle's needs and design constraints.

That covers the common lingo on the engine itself. There are plenty more terms (e.g., compression ratio, knock/pinging, EFI, catalytic converters, etc.), but armed with the above definitions you can hang in most bench-racing chats or at least understand what your car's spec sheet means. Now, let's look at a few counterintuitive facts and misconceptions about engines that often surprise people.

What Might Surprise You: Counterintuitive Facts & Myths

Even with the basics covered, the world of engines has some twists and turns that defy common intuition. Here are a few interesting or misunderstood aspects of combustion engines that might surprise the casual car owner:

Diesel Engines Don't Have Spark Plugs: As mentioned, a diesel relies purely on compression to ignite fuel – no spark. Many people are perplexed by how a diesel truck can run underwater or how it ignites fuel without a spark – it's because compressing air to ~20:1 ratio makes it so hot (800+ °C) that injected diesel spontaneously combusts. This also means you generally can't "rev" a diesel as high; the combustion process is slower. But diesels excel at producing lots of torque at low RPM and doing so efficiently, which is why big trucks and ships use them. It's a fun trivia to ask: "How many spark plugs does an 18-wheeler have?" Answer: zero! (Glow plugs don't count – those just help cold starting by pre-heating).

Most of Your Fuel Energy Becomes Heat, Not Motion: A typical gasoline engine might be ~25% efficient at turning fuel energy into mechanical work. The rest is lost as heat in the exhaust or absorbed by the cooling system. That's why engines need large radiators and why your car's exhaust gets hot enough to fry eggs. This inefficiency is one reason hybrids and EVs gained interest – electric motors can exceed 90% efficiency and waste very little energy as heat. It also means any improvement in engine efficiency (like running leaner, using higher compression, etc.) can directly increase power or economy. Historically, one big efficiency gain was electronic fuel injection and precise ignition timing – it reduced fuel waste (unburnt fuel) and allowed leaner mixtures when cruising. But still, every time you burn a gallon of gas, only a quarter of that bang actually pushes you forward – the rest warms up the engine block and the great outdoors. So don't feel too bad using your engine's heater in winter – you're just recycling some waste heat that would otherwise go out the radiator.

More Horsepower != Better Car (Necessarily): It's easy to get caught up in horsepower numbers. A higher-horsepower engine canmake a car faster, but vehicle performance also depends on weight, gearing, traction, and power delivery. For example, an 8,000 lb truck might have 400 hp but still be slow compared to a 2,500 lb sports car with 250 hp, because the power-to-weight ratio is worse. Similarly, a car with lower peak horsepower but lots of torque at low rpm might feel quicker in everyday driving. And then there's the matter of how the power is delivered – a peaky turbo engine might advertise big horsepower, but if all that power comes in a narrow RPM range, the car could be hard to drive fast except when you're flooring it. That's why test drives matter – specs on paper don't tell the whole story.

Turbo Lag and "Engine Breathing": Forced induction adds complexity – one common myth is that turbocharged engines are always better because they're more powerful. Yes, they can be, but turbo lag is real: that slight delay between pressing the throttle and the engine responding, as the turbo spools up. Modern engineering has minimized lag, but if you've ever driven an older turbo car, you know the feeling: nothing-nothing-nothing then WHOOSH as the boost kicks in. Supercharged engines don't lag as much, but they do put more strain on the engine (parasitic loss to drive the supercharger) and can heat the intake air a lot. There's also an effect on engine sound and rev character – many enthusiasts still love naturally aspirated engines (no turbo, no supercharger) for their linear response and sound, even if they make less peak torque. It's subjective, but worth noting that sometimes less tech can be more fun or at least more predictable in feel.

High Octane Fuel Myths: Many people think using premium gasoline (91/93 octane) will give their regular car more power or "clean the engine." The truth: higher octane fuel does not contain more energy. It's simply less prone to knocking (unwanted premature combustion) and is required for engines with high compression or turbo boost to prevent knock. If your car doesn't specifically require premium, using it won't magically make more power or mileage – you're just paying more for knock resistance you don't need. Conversely, if your car does require premium (say a turbo BMW), using regular can result in the engine computer retarding timing (to avoid knock), which reduces power and efficiency. So use the fuel grade your engine is designed for. The confusion likely arises because "premium" sounds better, and indeed in some older cars with no knock sensors, a higher octane could allow a bit more aggressive timing. But modern engines adjust on the fly. Consider this myth busted for most cases.

You Don't Need to "Warm Up" Modern Engines for Long: In the carburetor days, you had to baby an engine when cold – let it warm up, otherwise it might stall or stumble because carbs didn't mix fuel well when cold. Modern fuel-injected engines, however, manage cold start enrichment automatically and precisely. It is still good to allow about 30 seconds to a minute for oil to circulate on a freezing cold start, but idling longer than that is usually unnecessary and just wastes fuel. In fact, the best way to warm an engine is to drive it gently – that gets everything up to temp faster than idling. So if your dad taught you to warm the car for 10 minutes every morning – that was probably valid in 1975, but today's engines are ready to go much sooner. Save time and fuel (and emissions) by not overdoing the idling.

Engines Are Getting Smaller and More Turbocharged: You might have noticed that a lot of new cars have smaller engines than their older counterparts, yet similar performance. This is the trend of "engine downsizing." A modern 2.0L turbo-four can replace an older 3.0L V6, offering the same power but better fuel economy when not on boost. However, there's a trade-off in character – some lament the loss of smooth six-cylinders or burly eights. This is somewhat subjective, but it explains why, for example, the new Ford Mustang offers a 2.3L turbo 4-cylinder option alongside a traditional 5.0L V8. The four is more efficient and still quick (thanks to turbo), but the V8 gives that classic sound and linear power. Neither is "wrong" – it's about what you value.

Crazy Fuels and Engines: Did you know there was a car that could run on perfume or tequila? In 1963, Chrysler built a prototype called the Chrysler Turbine Car powered by a turbine engine (like a jet engine) instead of pistons¹⁵. It could run on virtually any combustible liquid – people famously poured in Chanel No.5 perfume, peanut oil, even tequila, and it ran. The turbine engine had almost no moving parts compared to piston engines and never needed oil changes in the conventional sense, but it had drawbacks: it idled at 22,000 RPM (!) and had sluggish throttle response. Only a handful of these cars were made for testing (and most were destroyed – Jay Leno owns one of the few survivors). It's a fascinating "what could have been." The project didn't go forward, but it reminds us that internal combustion isn't limited to pistons – there are other designs that were explored. For instance, Mazda championed the Wankel rotary engine (famously used in the RX-7 and RX-8 sports cars) which has no pistons, just a triangular rotor spinning in a chamber. Rotaries were very smooth and could make high power for their size (and rev to the moon), but they tended to consume oil and weren't as durable or efficient, leading Mazda to retire them for now. Still, the rotary's simplicity (only a few moving parts) and the turbine car's fuel flexibility show that the piston-engine dominance was never a foregone conclusion – it just turned out to be the best compromise for most purposes.

Famous Rivalries Built on Engines: Car history is full of colorful tales, but one of my favorites linking to engines is the Ferrari vs. Lamborghini feud¹⁴. Ferruccio Lamborghini was a tractor manufacturer who loved fast cars; he owned a Ferrari but was unhappy with it – the clutch kept giving him trouble. Around 1963 he went to Enzo Ferrari himself to complain and suggest improvements. Enzo, known for his pride, basically told Lamborghini to shove off: "Let me make cars. You stick to making tractors." Insulted, Lamborghini vowed to build his own supercars to beat Ferrari. Within just a few years, Lamborghini's new company produced the stunning Lamborghini Miura, the first mid-engine road supercar, which indeed shook up the sports car world. Lamborghini's cars, like the V12-powered Miura and later Countach, challenged Ferrari on the track and street, and a legendary rivalry was born – all because of a bruised ego and a clutch. (Oh, and irony alert: when Lamborghini's mechanics later examined the Ferrari's faulty clutch, they found it used the same supplier as Lamborghini's tractor clutches, just ten times the price!) The takeaway: sometimes the stories behind engines – of egos, competition, and innovation – are as entertaining as the technology itself.

We could go on with surprises, but these examples show that the internal combustion engine, for all its familiarity, has plenty of nuances. It's a roaring metal beast optimized over a century, full of quirks and clever tricks.

As we near the end of our journey, it's clear that a car's engine is far more than just "noise under the hood." It's an orchestra of precision parts performing a fiery symphony of physics. From Bertha Benz's day of gentle puffing along at 10 mph to today's 300 mph Bugatti chirping its turbos, the internal combustion engine has continuously evolved yet stayed true to the same basic principle of controlled explosions pushing pistons.

Wrapping Up: Understanding the Beast Under Your Hood

At this point, we've traveled from the dawn of motoring to the inner workings of modern engines, with detours through technical jargon and historical rivalries. Why does it matter? Well, beyond just satisfying curiosity, understanding how a combustion engine works can genuinely enrich your relationship with your car. The next time you turn the key (or push the start button) and hear that starter whirr and engine rumble, you'll know that a tiny electric motor just spun your crankshaft, your pistons started pumping, drawing in fresh air and fuel, and the whole machine came alive in a controlled burst of fire – thousands of little combustions per minute smoothly propelling you down the road. That's pretty awe-inspiring when you think about it.

It also means the next time your mechanic says something like, "Looks like you've got a bad camshaft position sensor and a leaky head gasket," you won't be mystified by the words. You'll recognize that the camshaft sensor helps track the cam timing (vital for fuel injection and spark timing), and a head gasket leaking is serious because it seals the head and block – oil or coolant might be sneaking into places it shouldn't. If they say "your tie rod ends are worn," you'll understand that's about steering, not the engine at all, but still important. In short, you'll be empowered to ask smarter questions and not get bamboozled by jargon.

Looking back to the historical anecdote that kicked this off: Bertha Benz likely didn't grasp every theoretical detail of the engine in her husband's Patent-Motorwagen, but she learned enough by experience to troubleshoot problems and keep it running. In a way, she was the first car mechanic too – cleaning fuel lines, improvising insulation, managing the engine's needs. She turned a mysterious invention into a practical vehicle for daily use. Similarly, by learning about our engines, we demystify them and gain confidence to engage with the technology rather than treat it as black magic.

The internal combustion engine is often called the "heart" of the car, and for good reason. It's a pulsing, thumping source of life for the vehicle, converting ephemeral chemical energy into motion, noise, and heat. It enabled the modern world's mobility, spawned industries and cultures (from the Ford assembly line to Formula 1 racing), and even today, as electric motors start to take the stage, the gasoline engine holds a beloved place in many hearts. There's a visceral thrill to it – the crescendo of RPM, the rear pushed into your seat under acceleration, the mechanical concerto of whirring valvetrains and burbling exhausts. It's mechanical art as much as science.

So the next time you're driving and you hear the engine purring (or growling, or maybe clattering if it's a diesel), take a moment to appreciate what's happening: hundreds of controlled explosions per second, perfectly timed, smoothly converted into motion by a feat of engineering ingenuity that's been refined over decades. Each part is doing its job in concert – the pistons pumping, the crank spinning, the cams conducting their valve orchestra, the spark plugs firing like tiny lightning bolts, the fuel injectors misting just the right amount of gasoline, all while being cooled, lubricated, and monitored by sensors. It's complex, yet it works so seamlessly we hardly think about it… until something goes wrong, of course!

With your new understanding, hopefully you'll find it a bit more fascinating than frustrating when you do have to think about it. That "check engine" light might still be annoying, but at least now you'll have a mental picture of what could be amiss behind it. And perhaps you'll even impress your friends by explaining the difference between horsepower and torque when someone mis-quotes that old phrase "horsepower is how fast you hit the wall, torque is how far you take it" (now you can clarify why that's not the whole story).

The internal combustion engine is a triumph of practical engineering, born in an era of tinkering inventors, matured through wars and races and oil crises, and still relevant in our daily commutes. It's noisy, it's not terribly efficient, and it's composed of so many moving parts that it's a wonder it holds together, yet it changed the world. Understanding its rhythms and parts is not just a technical lesson, but a way to connect with a century of innovation and the very object that provides us freedom of movement. So next time you pop your car's hood, don't just see a jumble of metal and plastic – see the story and the system: a Benz engine fumph-fumphing to life; a Ford assembly line cranking out Model T's; a Ferrari V12 wailing on a track; a turbo spooling up on your morning commute. Suck, squeeze, bang, blow – and off you go, carried by one of the most consequential contraptions ever created. Now you know what your mechanic knows – and probably a few fun things he doesn't. Safe travels, and happy motoring!

If you enjoyed this post, you will enjoy my book, “The Science of Free Will”: https://amzn.to/4aMQJD1.

References

Wired – Bertha Benz's historic 1888 road trip (the first ever)

https://www.wired.com/2010/08/0812berta-benz-first-road-trip/Invention & Technology Magazine – Energy density: gasoline vs. early electric batteries (~6000 Wh/lb vs 10 Wh/lb)

https://www.inventionandtech.com/content/why-internal-combustion-1Invention & Technology Magazine – Kettering's electric starter (1912) enabled gasoline cars' success

https://www.inventionandtech.com/content/why-internal-combustion-1James Madison Museum – Henry Ford's quote "any color… as long as it is black" (from his 1922 autobiography)

https://www.thejamesmadisonmuseum.net/single-post/any-color-the-customer-wants-as-long-as-it-s-black-henry-fordInvention & Technology Magazine – Early electric car cost (

$2800) vs. Ford Model T ($600) in 1913

https://www.inventionandtech.com/content/why-internal-combustion-1Catawiki – Enzo Ferrari's quote: "Aerodynamics are for people who can't build engines."

https://www.catawiki.com/en/stories/4259-9-enzo-ferrari-quotes-that-explain-the-cars-historyWikipedia (Four-Stroke Engine) – Description of the four-stroke cycle (intake, compression, power, exhaust)

https://en.wikipedia.org/wiki/Four-stroke_engineArt of Manliness (Gearhead 101) – Camshaft and valvetrain basics (cam lobes timing valve opening)

https://www.artofmanliness.com/skills/manly-know-how/how-a-cars-engine-works/MOOG Parts – Tie rod ends connect steering rack to steering knuckle (enable steering the wheels)

https://www.moogparts.com/parts-matter/all-about-tie-rods.htmlChristian Bros. Auto – Purpose of suspension (to maximize tire-road contact, absorb bumps for control and comfort)

https://www.cbac.com/media-center/blog/2018/december/a-smooth-ride-how-car-suspension-works/MotorTrend – Torque vs horsepower explained (torque = work, horsepower = work rate; formula HP = T×RPM/5252)

https://www.motortrend.com/features/what-is-torque-in-carsMobil (Exxon) – Turbocharger vs Supercharger difference (turbo uses exhaust gas, supercharger belt-driven)

https://www.mobil.com/en/sap/our-products/why-mobil/driving-performance-and-protection/turbochargers-vs-superchargers-how-they-workCarParts.com – Definition of redline (max safe RPM, indicated in red on tachometer)

https://www.carparts.com/blog/what-is-the-redline-of-an-engine-and-why-is-it-bad-for-your-vehicle/Granturismo Events – The Ferrari vs Lamborghini origin story (Ferruccio's complaint and Enzo's insult "stick to tractors")

https://www.granturismoevents.com/story-the-epic-story-behind-the-ferrari-and-lamborghini-rivalry/Reddit (r/TodayILearned) – Chrysler Turbine Car could run on alternate fuels including perfume, tequila, peanut oil, etc.

https://www.reddit.com/r/todayilearned/comments/ex5kjb/til_that_in_the_1960s_chrysler_created_a_car_the/